#Repetier server prusa i3 mk3 Pc

Just connect the printer to your PC via USB and start Pronterface.

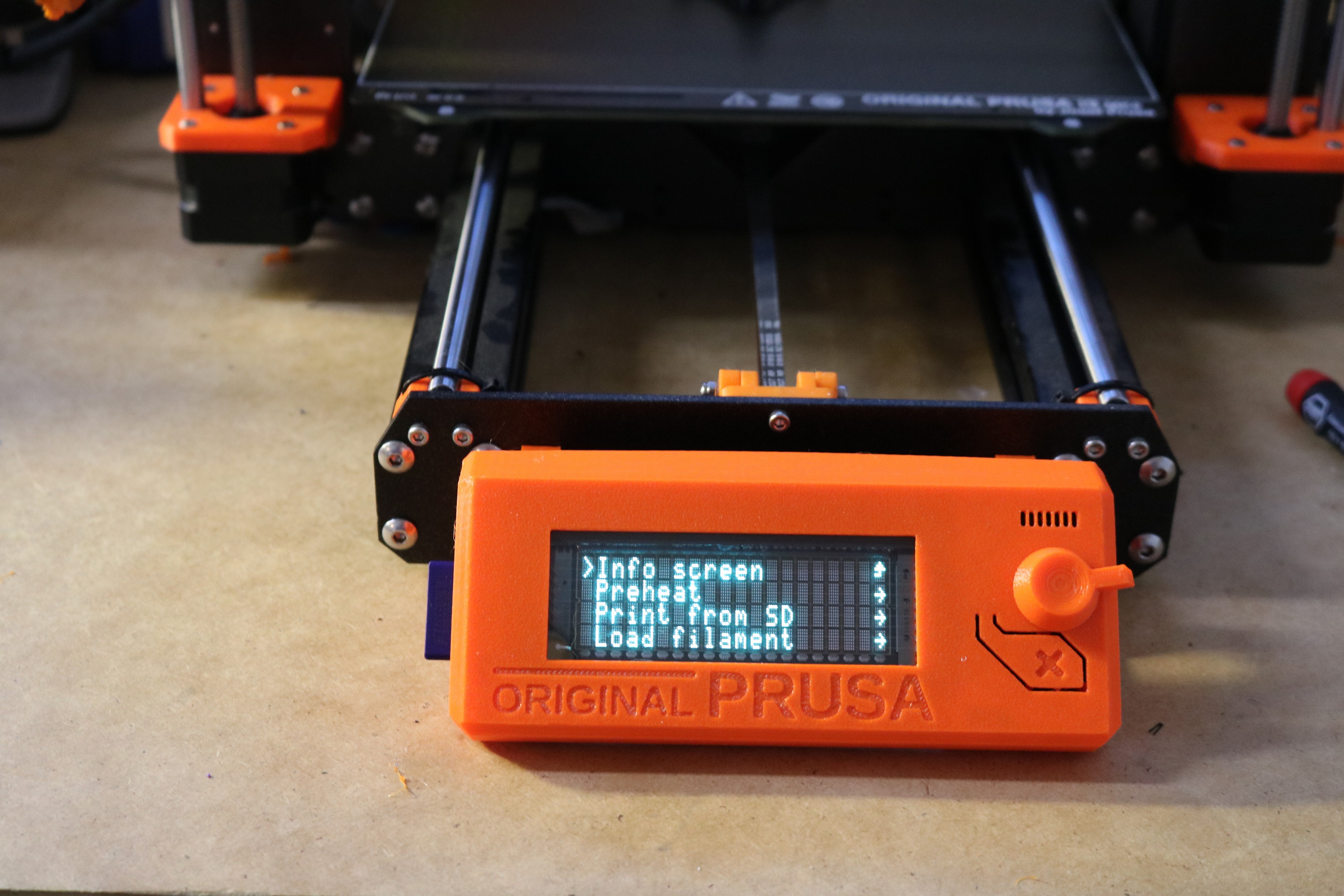

However, for some of the flat surfaces, the printer cannot handle the speed. The 300 speed works perfectly fine for some of the models. I need an interactive console to let me read values of stepper motor parameters, change & save. I am using PLA and I am looking for ideas on using the Tune option to tune my Prusa i3 MK3 to increase the speed to 300. I'm printing technical parts that requires some degree of accuracy: screw holes, bearing seat block and such where 0.1mm difference matters.īy the way, I think there's a way to send g-code in Prusa Slicer but that's not going to work for my purposes. Please help pointing me in the right direction. Repetier sees it (USB-to-serial port becomes available) but couldn't establish a working connection to the point I can use the console. On the Prusa i3Mk3 I couldn't seem to connect it properly to Repetier. M92 (enter new parameter for each stepper motor) On my other 3D Printer I would connect them to a Repetier server and in it there's a console that lets me send G-Code commands: In case you would still like to fine-tune it, you can long-press the knob while the first layer is printed.Posted by: printed 20x20 test cube and the print was off-measurement. The Original Prusa MK4 and Original Prusa XL are equipped with a loadcell, which will calibrate the first layer automatically. From here you can adjust it by rotating the knob. This will show the Live adjust Z value you have set in the First layer calibration.

The most common approach is to perform the Live adjust Z during the print.

#Repetier server prusa i3 mk3 manual

The exact position can slightly vary, use the last chapter of the assembly manual of your printer to set the rough distance.Įxample of the MK3S extruder Live Adjust Z (while printing) The correctly assembled print head has the sensor always slightly above the nozzle, never at an equal level or below the nozzle (see the picture below). Going above zero into the positive values is not possible, this indicates either an issue with the measuring sensor (M.I.N.D.A., P.I.N.D.A., SuperPINDA) or incorrect alignment. The values of the Live adjust Z are typically in the range of -1.500 to -0.200. to get further from the print surface, turn the knob clockwise and continue lowering the negative value (e.g.to get closer to the print surface, turn the knob counter-clockwise and further increase the negative value (e.g.the default value before the First layer calibration starts at zero (0.000) for all printers.

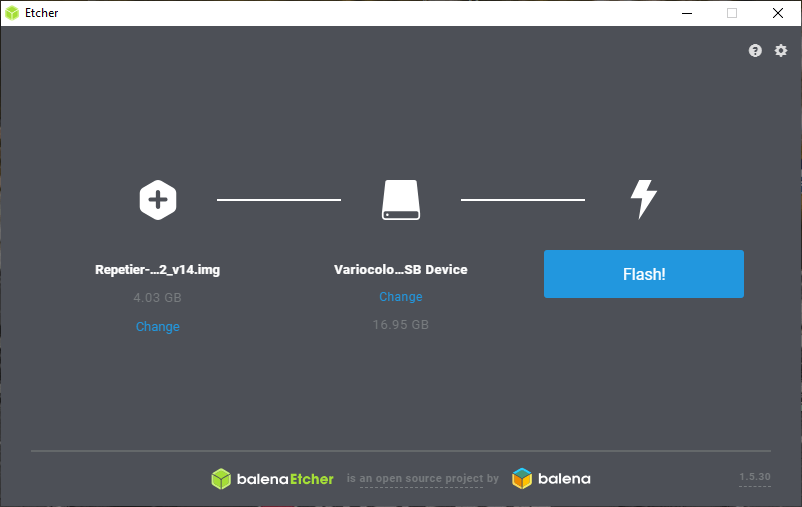

The reason for adjusting the distance is to mostly provide better adhesion of the extruded filament. Sometimes this value needs a slight adjustment and for this situation, there is an option called " Live adjust Z" (as you are mostly tuning it live during the first layers of your print). The file name with the firmware for the MK3S is prusa3dfwMK3Sxxxxxx where the x is the firmware version number.

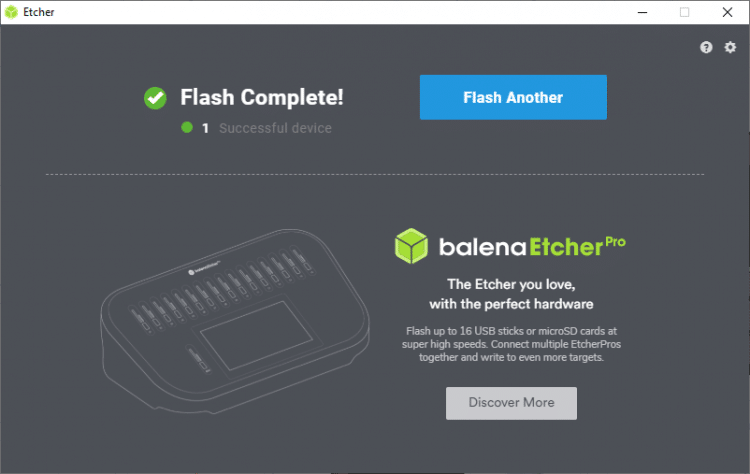

hex file from the location you unzipped it. Click on the Browse button ( green arrow right picture) and choose the. Every FFF (Fused Filament Fabrication) printer requires a First Layer Calibration, which sets the vertical "Z" distance between the nozzle and the print surface. Open PrusaSlicer, click on the 'Configuration' menu, and select 'Flash printer firmware' (left picture).

0 kommentar(er)

0 kommentar(er)